Process overview - sheet processing and laser cutting

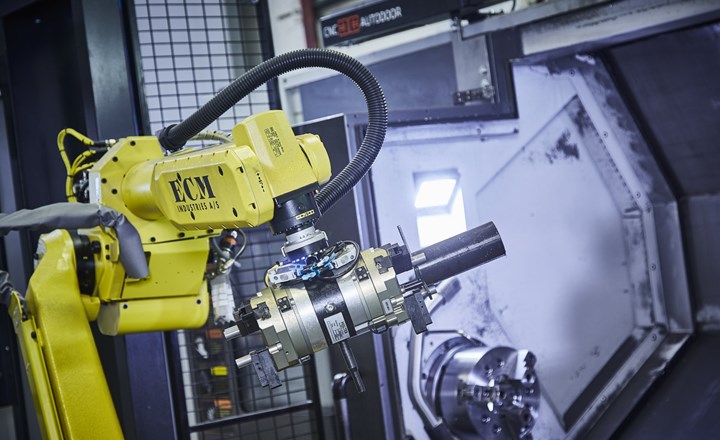

Our services range from the initial idea to the finished product. ECM industries A/S possesses all of the latest technologies within sheet processing: laser cutting, turret punching, edge compression, and robotic welding.

Quality certification

ECM INDUSTRIES A/S ensures your interests through quality certification when it comes to:

Contact us

It's our goal to have close dialogue with our customers

We are ready to receive your call or email.