SHEET METAL WORK

Precise Laser Cutting and Bending at ECM INDUSTRIES A/S

Our experienced team specializes in laser cutting and bending, always striving to meet our customers' needs and requirements. At ECM INDUSTRIES A/S, we prioritize quality, accuracy, and finish in our work.

We are at the forefront of laser cutting technology. Recently, we have invested in a 20KW BYSTRONIC laser cutter with a 100-ton high storage capacity, offering fully automatic plate loading and automatic sorting of finished parts with robots.

The machine is fully integrated with our BYSTRONIC press brakes, ensuring 100% precision between laser cutting and bending.

We excel in laser cutting stainless steel, aluminum, brass, copper, steel, and checker plates. Our modern laser department is equipped with advanced machines, including a 20Kw fiber laser and an 8Kw Bystronic Fiber laser, enabling efficient cutting with MIXGAS and auto nesting programming.

We offer cutting to individual dimensions and requirements with a tolerance of +/-0.1 mm. Our laser department has the capacity to cut plates up to 50 mm thick and sizes up to 1500x3000 mm and 2000x4000 mm.

We serve a wide range of industries, including offshore, defense, food, infrastructure, and agriculture, with our laser cutting services.

We meet all requirements for certification of material reclassification, ensuring traceability and quality in our products.

Contact us today for tailor-made laser cutting solutions of high quality and precision.

Deburring and Edge Rounding

Sharp edges on sheet metal parts can lead to damage during handling or cutting wires when installed on a machine, so it is important to avoid them. Rounding the edges will also result in a thicker coating at the edges after surface treatment. In modern sheet metal processing, deburring or edge rounding is a standard procedure.

A deburring and edge rounding machine is tasked with achieving a consistent result on all edges, regardless of the contour of the workpiece. The abrasive tools should also wear evenly to avoid time-consuming calibration or readjustment. Our deburring and edge rounding machines meet all these requirements: they provide uniform 360° processing of parts along with a fine finish, and the degree of edge deburring can be adjusted from light to heavy. ECM INDUSTRIES A/S has the latest in rotating brush heads with eight counter-rotating brushes. The rotating head rotates about a vertical axis while sweeping across the workpiece. This results in a very uniform 360° processing from all angles and directions. Monochrome edge deburring up to a radius of 2 mm is now possible.

Our machines are equipped with a grinding belt station in front of the rotating head for either deburring or finishing applications. This grinding belt station has a unique floating head system that allows the entire unit to shift position if the grinding pressure becomes too high. This system prevents overheating of the workpiece, ensuring quality.

We also offer vibratory deburring with carborundum stones, vibratory deburring/polishing with ceramics, and coarse tumbling of parts.

Precision Bending

For over 45 years, ECM INDUSTRIES A/S has been experts in bending, and our experienced team always ensures high quality and accuracy. Regardless of the task's complexity, we take pride in meeting our customers' requirements and expectations.

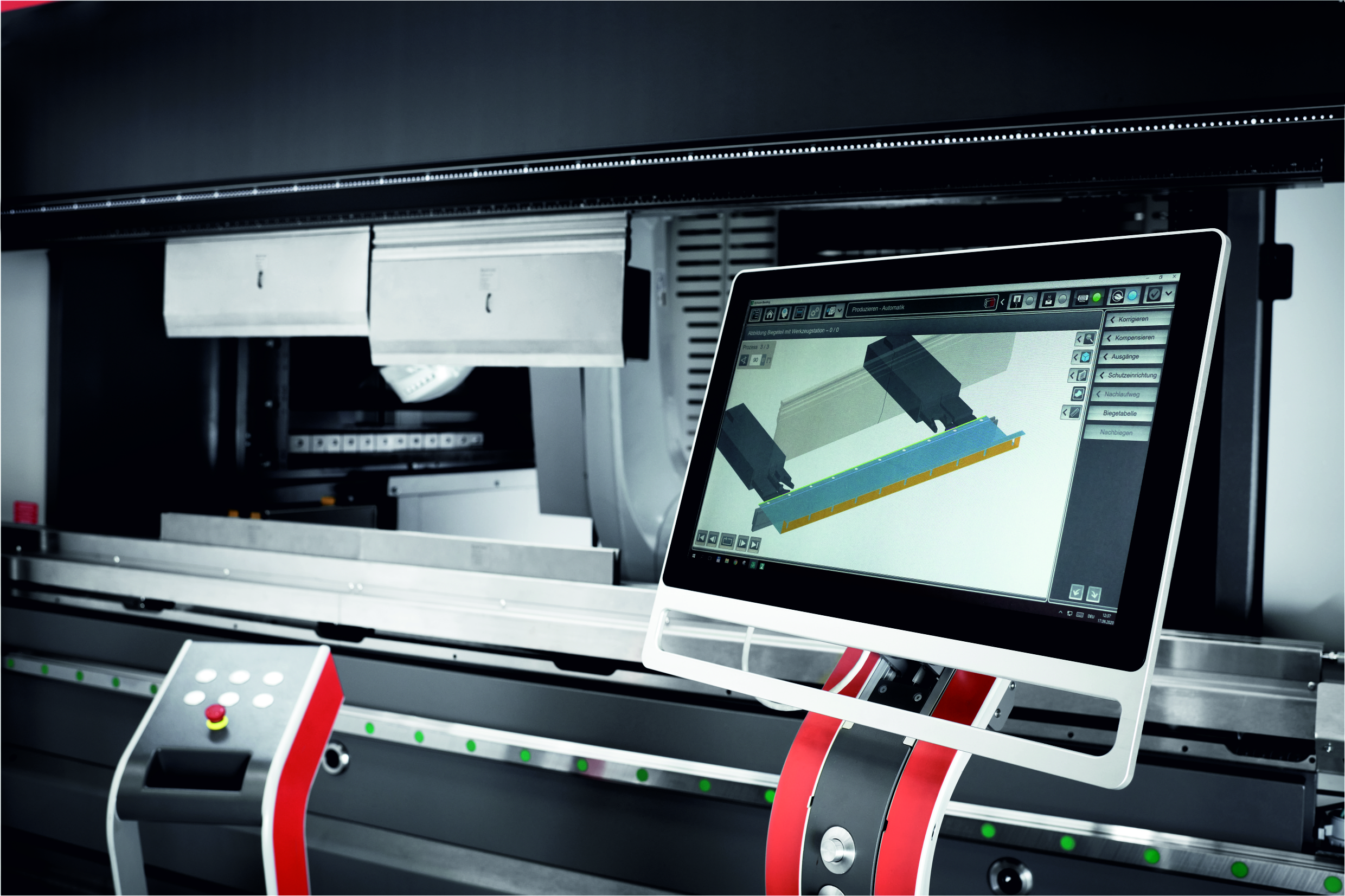

Advanced Equipment for Bending

We have three advanced press brakes at ECM INDUSTRIES A/S with an impressive capacity of up to 220 tons of pressure and a width of up to 4000 mm. Our machines are integrated with offline programming, which, together with our laser cutter, ensures correction for spring-back and high quality for the benefit of our customers.

Intelligent Pressure Monitoring for Precision

Our press brakes are equipped with intelligent pressure monitoring that continuously corrects the angle during the process, ensuring precise bending. This allows work with small tolerances and maintains the desired angle throughout the process.

Contact ECM INDUSTRIES A/S today for professional bending that meets your precise requirements.

ECM INDUSTRIES A/S possesses some of the market's most advanced bending machines. Our bending machines are fully integrated with our laser cutter. This ensures 100% precision between laser cutting and bending. We bend in all sizes and with different bending tonnages and batch sizes.