OUR STORY

1857

1863

1972

1974

1977

1979

1980

1980

1987

1993

1994

1997

1998

2002

2007

2010

2014

Erik and Karin Christiansen started the company on February 15, 1977. Exactly 40 years later, their sons took over the business.

But the history goes much further back. Karin's father, grandfather, great-grandfather, and great-great-grandfather were the old blacksmiths in town. And after nearly 2 years of closure, from 1975 to 1977, Erik and Karin reopened the smithy in the old buildings. Below, you can read much more about the more than 165 years of history.

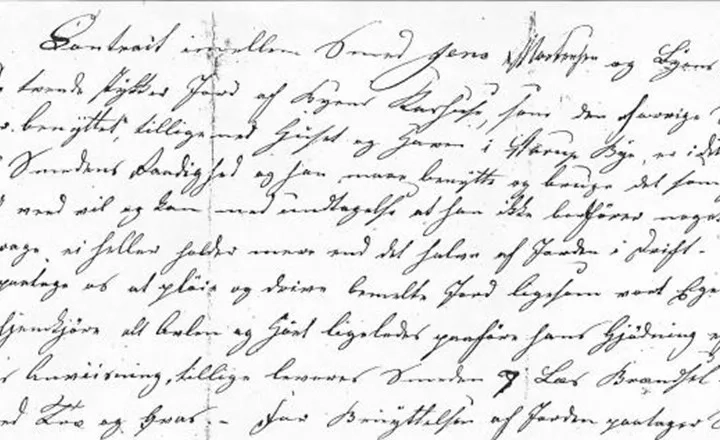

Blacksmith Jens Mortensen was hired as a contracted town blacksmith in Øster Starup.

At that time, five of the village's farms stood as owners of the modest smithy, and according to the contract, blacksmith Jens Mortensen was to perform repair work for them free of charge when they provided both iron and coal.

However, they were required to pay for blacksmith work that did not involve repairs.

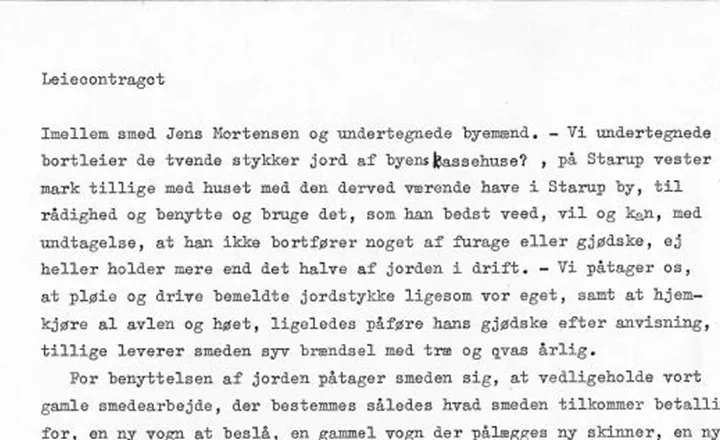

The lease agreement was entered into on February 28, 1863, by Blacksmith Jens Mortensen. The lease commences on May 1, 1863, and continues thereafter for 5 years.

From village blacksmithy to specialized factory. Previously, the main business of the blacksmithy was repairs.

These are still carried out, but there is a focus on new areas such as the installation of sanitation, water, and heating systems, as well as the custom manufacturing of spiral staircases.

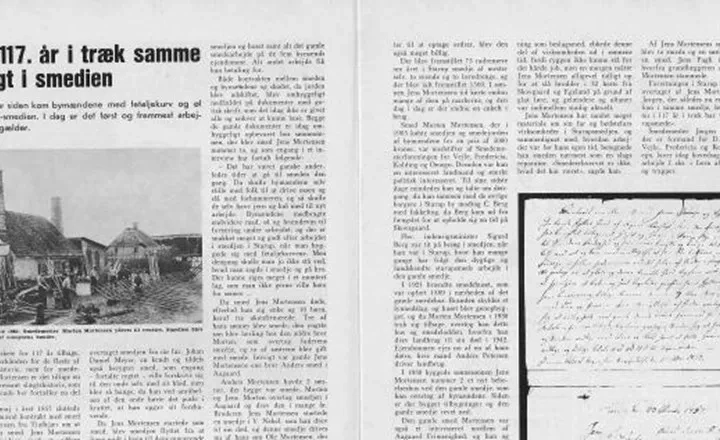

For the 117th consecutive year, the same lineage in the blacksmithy. Article in the Danish Smiths' Gazette.

On February 15, 1977, Erik Christiansen starts Øster-Starup Smithy and Machine Workshop (Øster-Starup Smede- og Maskinværksted.)

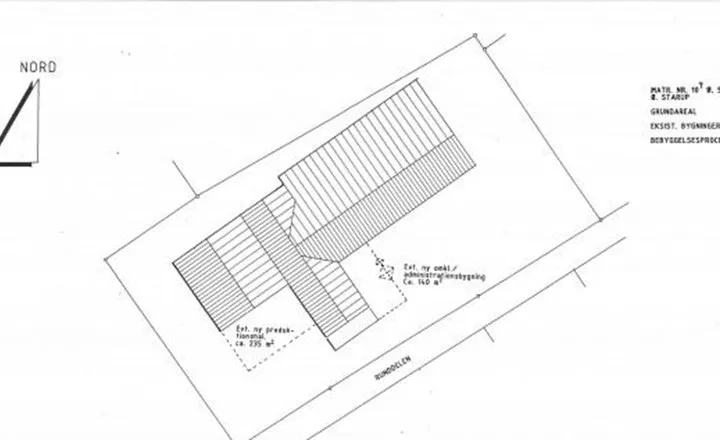

Øster Starup Village Smithy, now in its fifth generation, erects a large new factory hall. The new hall spans 300 square meters.

In the spring, it relocates from the old smithy to the new buildings. At this time, the company has extensive deliveries to the domestic industry, and large parts of the production are sent out of the house as semi-finished products and further distributed.

The company receives an order for a straw-fired boiler for the British Royal Family. The company moves to new premises at Runddelen 11.

The company celebrates its 10th anniversary. At this point, there are 10 employees, and the company is busy with order work for businesses across the country. 40% of the production is for export, and 35% is the company's own production.

At this point, there is such a good demand in sheet metal processing that work is carried out in three shifts. In September 1993, the hall is ready, and an entirely new set of machinery is installed.

At this point, the company has approximately 2000 square meters of space and employs a staff of 34.

The company celebrates its 20th anniversary. In addition to the factory at Rundelen in Øster Starup, they have a branch in Vester Nebel, where they operate with two shifts, while there are three shifts in Øster Starup. At this point, there are 47 employees.

In early November, the company is awarded the "Knøw Prize" by Egtved Municipality. The prize is awarded as an appreciation for a commendable effort supporting the municipality's business policy.

The prize is presented on November 6, 1998.

The company celebrates its 25th anniversary. Expansion includes the addition of a new hall housing an advanced punching machine. At this point, there are only three similar machines in Denmark.

The company now employs 48 people.

The company celebrates its 30th anniversary. At this point, the company owns nearly 4000 square meters of space and employs 60 people.

EC Maskinfabrik changes its name to ECM Industries A/S. The change is motivated by a significant increase in exports to customers in markets such as the United States and China.

The name change also signifies the company's readiness to adapt and its determination to keep pace with developments in global competition.

The certificate propels ECM to the top. On July 1, 2014, it became a legal requirement for blacksmith companies in the construction industry to obtain certification.

ECM chose to obtain the EN1090 certificate as early as 2013.